Slicelab spearheads concrete household furniture using 3D printing technological know-how

U.S.-primarily based experimental layout studio Slicelab has created a novel concrete table using a 3D printed mildew.

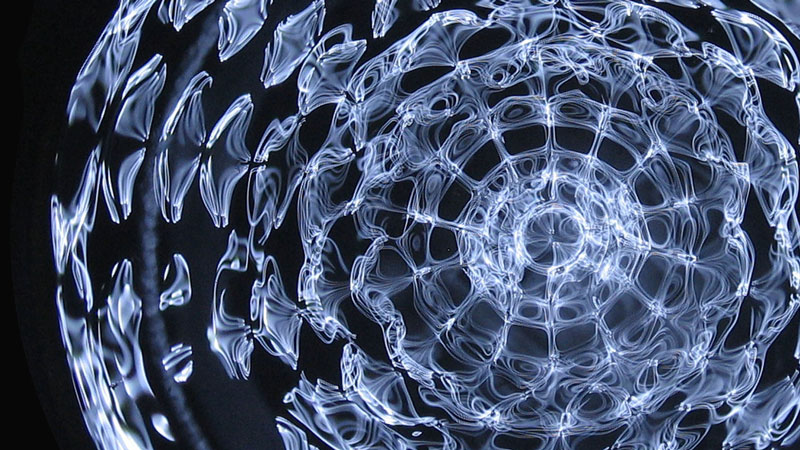

The creative household furniture piece is identified as the Sensitive Density Desk, and it capabilities a fluid, nearly added-terrestrial form. Weighing in at 86kg and measuring 1525 x 455 x 380mm, the desk is cast completely out of white concrete, putting a ‘delicate balance’ among aesthetic kind and hugely-purposeful product density. The business embarked on the undertaking in a bid to see just how summary and thorough concrete can get although continue to being structurally rigid.

Slicelab writes, “The intent of this job was to exploration a new fabrication and mold producing strategy for complicated concrete types by applying 3D printing. With concrete’s potential to just take on any form, it shares a potent similarity to how rapid prototyping is able to make just about any geometry. The potential of combining these two mediums was seen as a excellent possibility.”

Locating the magnificence in concrete

As a content, concrete has a very large compressive toughness, earning it the go-to selection when it will come to buildings and load-bearing architectural structures. However, it is also a very brittle content when made use of to generate finer geometries that expertise an abundance of rigidity.

“This exploration was geared towards the comprehension of what that minimum threshold of fragile kind it can take on was, all though holding the material’s full capability of energy,” writes the organization.

This equilibrium was struck employing a mixture of digital simulation and structural optimization technologies, which resulted in a predetermined geometry boasting both equally delicacy and higher-toughness. Critical to the achievements of the project was the geometric freedom granted by 3D printing, which definitely enabled the staff to carry on without the need of any hindrance in the way of structural feasibility or manufacturing prices.

A 23-portion 3D printed mildew

Owing to the table’s huge body, the design for the 3D printed mold experienced to be broken down into 23 person elements. Just about every of these elements was optimized and oriented to lessen the use of guidance constructions in the course of the construct – a shift which would go on to streamline the assembly approach. When printed, all 23 elements were being consolidated alongside one another to kind just one singular PLA mildew, which alone had a hearty pounds of 30kg.

Slicelab included, “This is unparalleled in the classic mildew producing tactics often witnessed all through the area of concrete casting.”

The mould was designed to be crammed upside down, with the ten legs performing as obtain points to the principal cavity. Further than just ease-of-use, this deliberate style option was created to create a gradient in the texture of the concrete desk. Especially, the method ensured that the air bubbles in the concrete have been limited to the underside of the table, leaving the prime area no cost of blemishes for two very contrasting seems.

The moment the Fragile Density Desk was launched from its mildew, the crew discovered that the surface complete mimicked the layer strains of the FFF-printed casing. Diamond pad moist sanding was eventually utilized to realize a mirror-like sheen.

Beyond just its use instances in engineering and business, 3D printing also has several applications in the artistic area. London-based cultural heritage project Scan the Environment has teamed up with Google Arts & Lifestyle to expand its selection of open up-source, 3D printable art. The partnership will leverage Scan the World’s experience in open info and 3D printing technologies and Google Arts & Culture’s storytelling system to set 3D printable artefacts in the fingers of fans, educators, and artists.

Elsewhere, at this year’s digital Acquire art honest, Maltese ceramic artist Nico Conti showcased a amount of his intricate 3D printed porcelain sculptures. The creation of the distinctive structures involved mixing laptop structure and 3D printing with inspiration from classical ceramics, architecture, and character, in purchase to purvey things of “distortion, collapse, and damage.”

Subscribe to the 3D Printing Sector publication for the most recent news in additive production. You can also keep linked by adhering to us on Twitter and liking us on Facebook.

On the lookout for a occupation in additive producing? Stop by 3D Printing Work opportunities for a assortment of roles in the industry.

Featured impression reveals Diego Taccioli and Arthur Azoulai of Slicelab sitting at the Fragile Density Desk. Image by means of Slicelab.